Company Profile

Pinjection is a Private Joint Stock company that specializes in:

- Research and development of high-precision plastic-based injection devices,

- Mass production of high-precision injection pens including:

o Production of medical-grade plastic-based components,

o Assembly of components into final products, and

o Quality control of medical devices.

- Design and development of process machinery for production line including:

o High-precision plastic injection molds, and

o assembly line for production.

Pinjection has a strong human capital in high-precision manufacturing, automation and robotics. Pooyesh injection employs high standards to maximize safety and user satisfaction.

Our team

Our experts in precision manufacturing, robotics, pharmacology and computer science started research in 2019. We simulated, designed and manufactured injection molds to produce high precision plastic parts. In addition, we developed a robotic assembly line. Today our team consists of over 100 engineers, scientists and manufacturers.

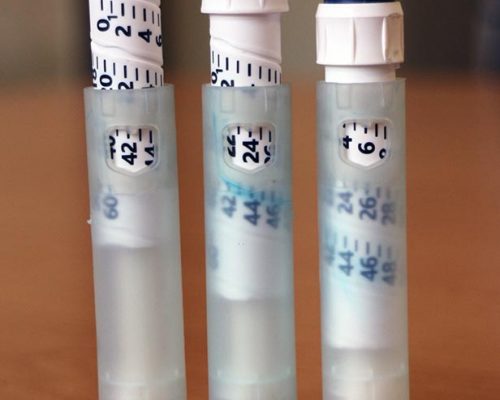

The insulin pen

Our insulin pen has passed a wide range of rigorous dosing and functional tests. These tests including dosing accuracy after exposure to temperatures of -20 to +70 degrees Celcius in addition to physical stress (vibration and fall). The tests also include physical stress. Functional tests measure the force and torque required for 12 different functions of the pen(injection force, needle installation/breakage torque, etc.). We pass all ISO tests in addition to several more complex tests that are not required by ISO.

Market History

- Used in marketed drug combination products in the middle east.

- Post Market Clinical Follow-up (PMCF) completed and documented.

- IFDA approved since May 2022.

- Implemented and maintained quality management system for disposable injection pens, certified by CISQ/IMQ.

Feel free to contact us at info@pinjection.com for more information and samples.